Originally published in The Washington Post

Last August, after heroic efforts by a bipartisan group of senators, critical legislation aimed at addressing the United States’ woeful weakness in producing high-performance semiconductors became law. An A-team led by Commerce Secretary Gina Raimondo and Michael Schmidt, an economic policy veteran, was given responsibility to dispense $39 billion to worthy manufacturers.

But now the success of the Chips and Science Act is threatened by a flotilla of unrelated objectives and unreasonable restrictions that Congress and parts of the administration have attached to the grant-giving process.

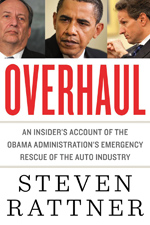

Having led, in 2009, President Barack Obama’s auto-rescue task force, the largest industrial policy adventure since the World War II mobilization, I’ve experienced the challenges and opportunities of government intervening in the private sector to solve a pressing problem.

My biggest takeaway: These adventures work best (or, perhaps, work only) when the mandate is to focus on the central objective and not pursue other goals, however worthy.

Such were the instructions that we received from Obama, who stood firmly behind us even as others pushed to broaden our objectives.

Regrettably, the chips project has been subjected to all kinds of extraneous guidelines, preferences and requirements.

Consider just one small section from a Commerce fact sheet: Applicants will be evaluated based on their plans to “create opportunities for minority-owned, veteran-owned and women-owned businesses; demonstrate climate and environmental responsibility; invest in their communities by addressing barriers to economic inclusion; and commit to using iron, steel, and construction materials produced in the United States.”

The documents also ask for commitments to affordable housing and to investing in K-12 schools and community colleges.

When it comes to the labor force, the marching orders are even more stringent. Much attention has been paid to the requirement to provide child care for employees. But the strictures go much further. Applicants are essentially required to hire union workers, including “economically disadvantaged individuals.”

They should collaborate with “workforce partners” ranging from educational institutions to “workforce development organizations” and create “sectoral partnerships,” whatever that means. And they should detail their “wraparound services to support individuals from underserved and economically disadvantaged communities,” including transportation or housing assistance.

Then there are restrictions on stock buybacks and dividends. I understand why we don’t want to use government money for these activities, but, beyond that limitation, companies should be free to manage their capital as they see fit.

Perhaps the biggest challenge confronting the chips team is that, under the National Environmental Policy Act, projects built with federal assistance are subject to lengthy reviews, which over the past decade have averaged 4½ years.

This is on top of myriad other permits and approvals on the local, state and federal levels, all of which may delay projects and prove daunting to applicants.

I could find only the barest mention in any of the Chips Act documents of the critical problems this tortuous permitting process creates. And even this mention incorrectly puts the onus on applicants to navigate excessive red tape.

No one should doubt the difficulty of the task facing the chips team. The United States has fallen woefully behind in the production of these critical components, the 21st century’s version of oil. We produce none of the most high-performance chips. Taiwan Semiconductor Manufacturing Company churns out 92 percent of the world’s supply; South Korea makes the rest. This concentration of production in a nation in China’s crosshairs represents a national security threat that the Chips Act correctly tries to address.

But while TSMC has committed to build a major facility in Phoenix, it has complained that the new plant’s cost will be much greater than its equivalent in Taiwan, partly because of regulatory requirements, higher labor costs, lower productivity, likely construction delays and higher taxes.

In a podcast interview, Morris Chang, the 91-year-old founder of TSMC, who was born in China and made his early career in the United States, acknowledged the national security considerations but called U.S. semiconductor efforts “a wasteful and expensive exercise in futility.” He noted that his company has had a smaller facility in Oregon for 25 years, and chips made there cost 50 percent more than those it manufactures in Taiwan.

It is doubtful that TSMC will ever manufacture its most cutting-edge chips in the United States; their exclusive production in Taiwan represents a “silicon shield” against a possible Chinese takeover.

Recognizing these challenges, the United States needs a better strategy for the chips war. In a perfect world, Congress would revisit the legislation, provide an exemption from the National Environmental Policy Act and remove the many other constricting provisions.

Realistically, it will fall to the White House to scale back the requirement to consider factors extraneous to meeting the chips challenge.

Europe is marching forward with its own set of subsidies, and Asian countries have been supporting their semiconductor makers for decades. Just last week, South Korea announced plans to build the world’s biggest chip-making base, with Samsung investing about $228 billion, and the government providing tax incentives and other assistance.

We’re facing a financial version of an arms race that we need to try harder to win.