Originally appeared in The New York Times.

A couple of weeks ago, I was honored to be invited to present my thoughts on the state of manufacturing in America to the Senate Democratic Steering and Outreach Committee, headed by Amy Klobuchar of Minnesota.

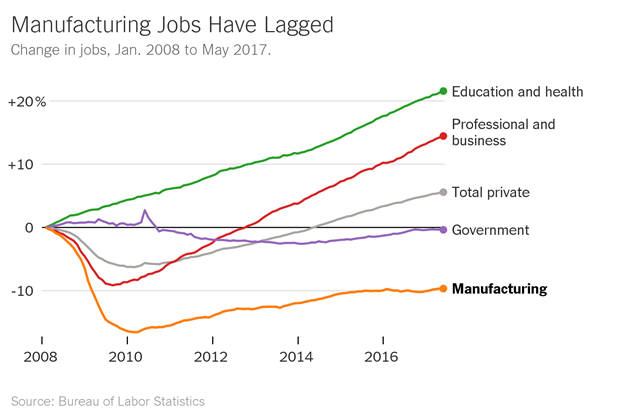

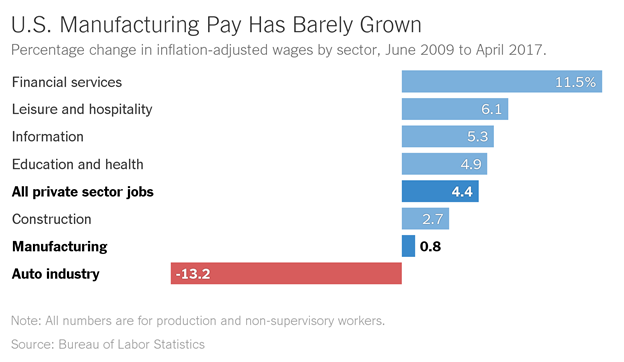

The thrust of my message was that, regrettably, we should be leery of proclamations of a renaissance of “Made in America.” Job growth in the industrial sector continues to be anemic and at least equally important, wage improvements have been marginal.

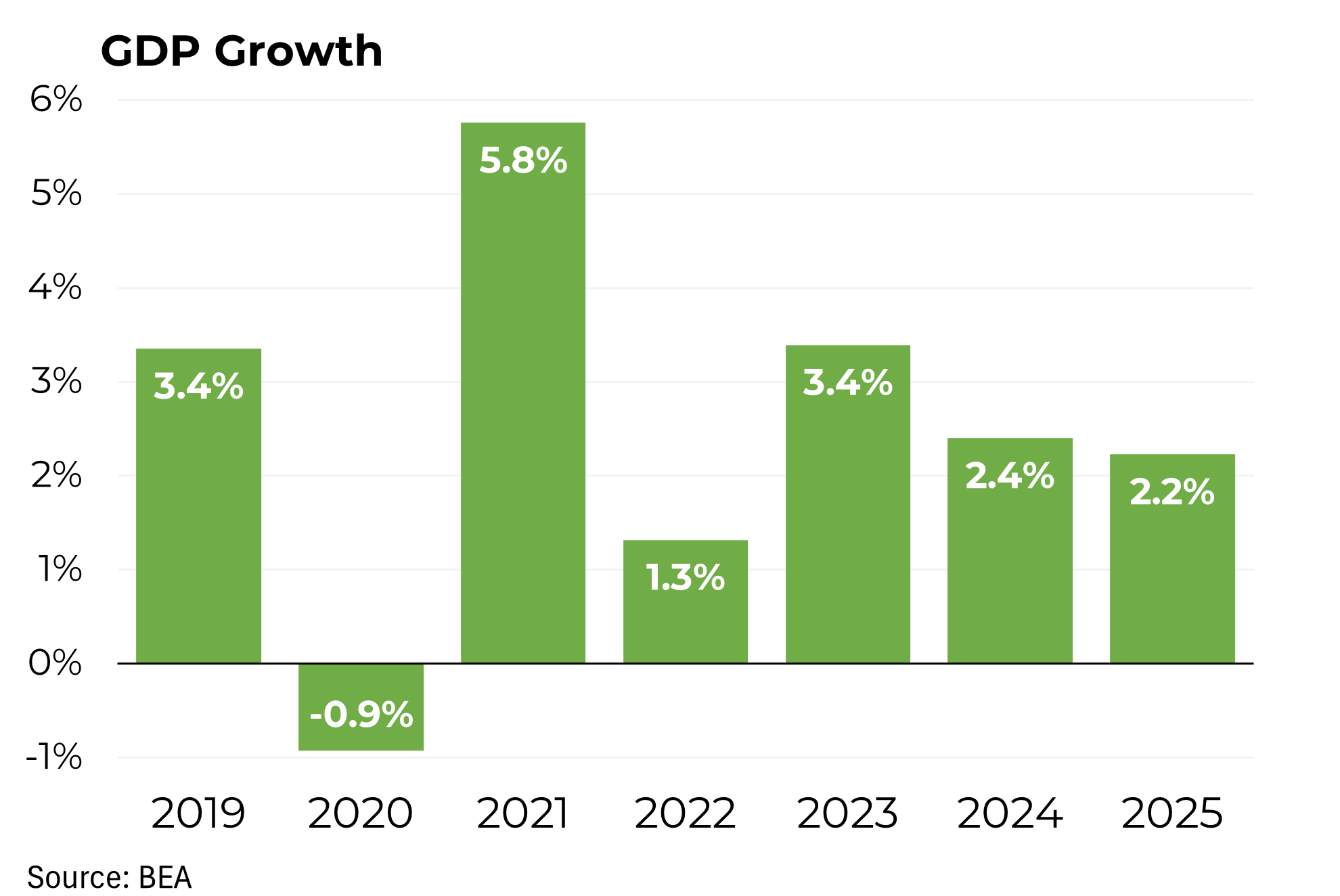

Below are nine charts that I presented to illustrate the situation. I closed with a list of suggestions — no magic bullets — for how to maximize the performance of our manufacturing sector. For the charts whose takeaway is not self-evident, I’ve provided some brief commentary.

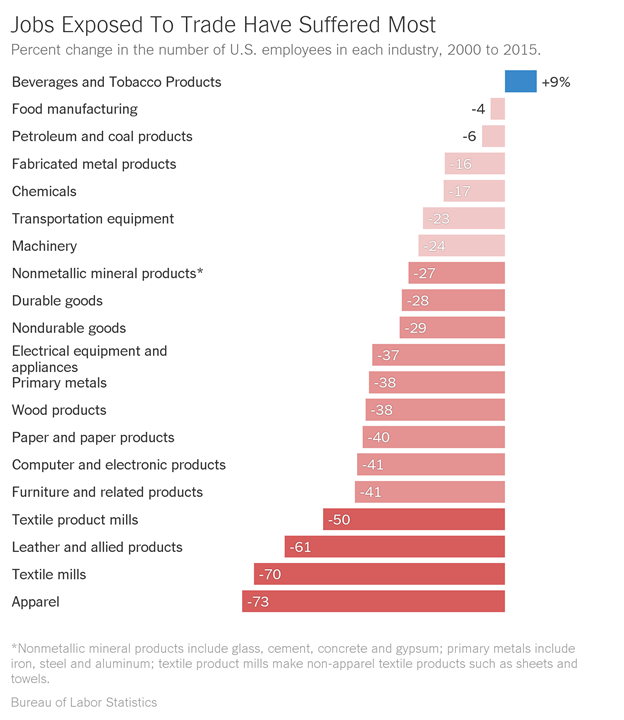

In my opinion, the crux of the problem is that we are competing in large part against countries — notably Mexico and China — that have gotten better at making things at a much lower labor cost. Even highly technical products — like airplanes — are beginning to be assembled in these countries.

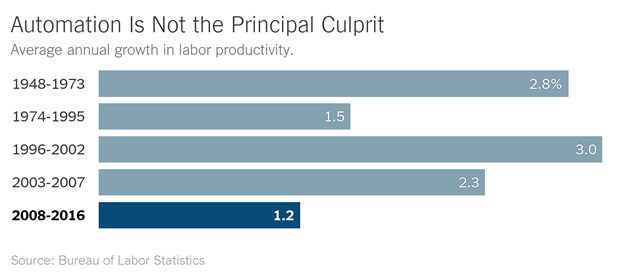

Automation (or robots) certainly played a role in the loss of manufacturing jobs before the financial crisis and may play a similar role in the future. But at the moment, robots are simply not the problem, as indicated by the low productivity numbers. If robots were the problem, our worker productivity would be growing faster, not slower, than it has in the past.

The job loss — particularly in areas most susceptible to competition from countries with low-cost labor — has been remarkable.

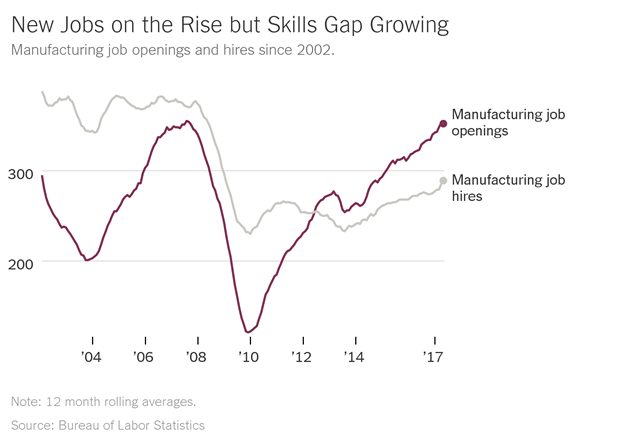

Here’s a ray of hope and an example of what’s needed. Since 2012, the number of job openings in manufacturing has exceeded the number of people hired. That indicates that companies are trying to hire (good news) but are having trouble finding workers with adequate skills (bad news — but an opportunity). Better training and education are among our best hopes.

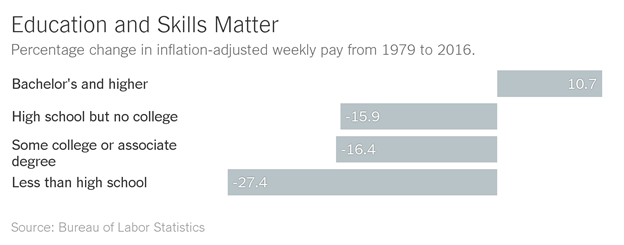

See what education can do for an individual’s income — and what happens to those without college degrees. That said, I understand that four years of college is not for everyone. That’s where better technical training (and yes, apprenticeships) can play an important, positive role.

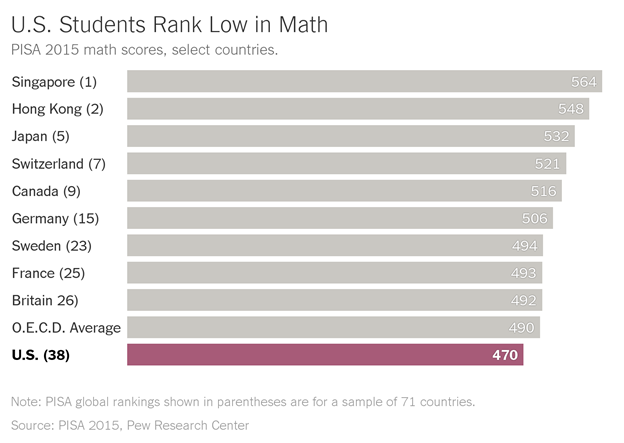

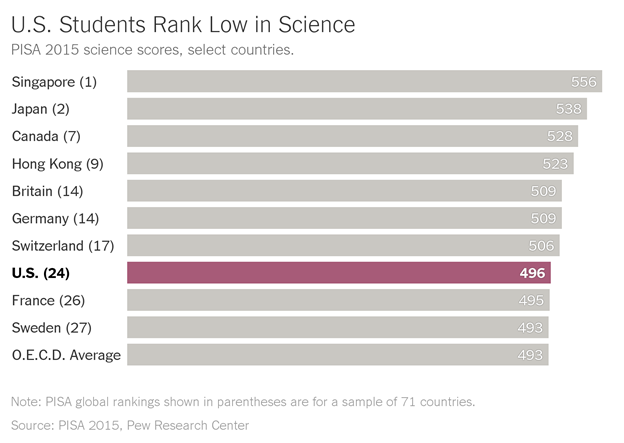

While I appreciate the importance of humanities and other nontechnical disciplines, we are in tough shape relative to other countries when it comes to math and science.

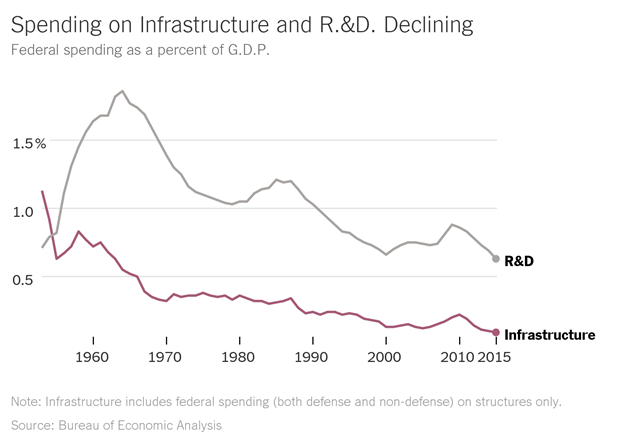

As the chart below shows, the call for more spending on infrastructure has sound basis in the numbers. As a share of gross domestic product, investment in infrastructure is at its lowest since before World War II. What doesn’t get as much attention — but should — is that spending on basic research, an important function of government, has also dropped to an historically low level. President Trump’s budget proposes to cut this further.

As I said at the outset, I have yet to sight a magic solution to our manufacturing challenges. Inevitably, manufacturing will continue to decline as a share of our economy, as it is doing in almost every other developed country. However, there are a number of specific policy actions that would make us more competitive and also ameliorate the harsh impact of the new competitive realities on our workers:

■ Better education (particularly in science and math) and training.

■ Tax reform, including sensible corporate tax policy and more progressive taxation.

■ Fair (but free) trade.

■ Higher federal investment spending on infrastructure and research and development.

■ Regulatory reform to facilitate business without sacrificing labor, environmental and other standards.

■ Increasing mobility to encourage workers to move to where the jobs are.

■ A better social safety net for those left behind.